Low Speed Surface Aerator

The TWISTER Low Speed Aerator delivers unmatched oxygen transfer and long lasting performance to many wastewater treatment processes.

From Activated Sludge to Oxidation Ditch and Extended Aeration Operations, the high O2 transfer of the TWISTER® aerator makes it ideal for high oxygen demand biological treatment applications in municipal, petrochemical, pulp & paper and other industries.

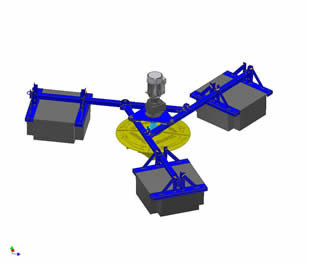

TWISTER® aerators can be configured as a floating unit using a three pod stainless steel float and support infrastructure or as a fixed unit using an adjustable mounting plate for optimal operational performance. The TWISTER® aerator is now available in a coated frame and non-metallic float option.

With a huge installed base of thousands of units around the world, TWISTER® aerators are reliable, well tested technology for many of your wastewater treatment needs.

Find out more

The TWISTER® Low Speed Surface Aerator offers high oxygen transfer and reliable operation to meet the requirements of your toughest wastewater treatment environments.

The TWISTER® Low Speed Surface Aerator offers high oxygen transfer and reliable operation to meet the requirements of your toughest wastewater treatment environments.

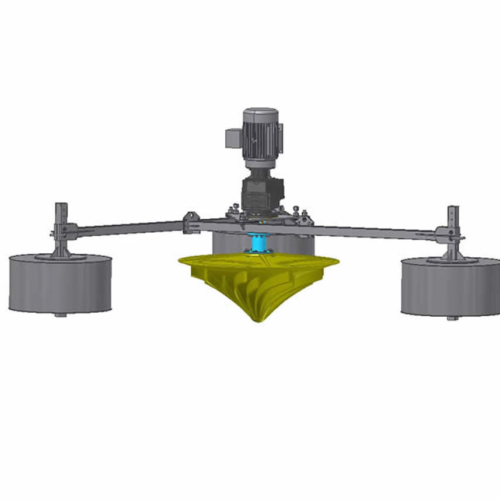

Designed for long-term continuous operation, the TWISTER® aerator utilizes an innovative composite material in the construction of its hydro-dynamically efficient rotor. The rotor is specially molded to optimize the spray of water droplets resulting in some of the highest oxygen transfer rates of any mechanical aeration system. Using the latest in power transmission technology, the TWISTER® aerator converts the least amount of energy into the maximum amount of rotor torque for excellent aeration and deep basin mixing. Models are available from 2 to 150 horsepower (1.5 to 110 kw) at 50 or 60 Hz.

TWISTER® aerators integrate the most recent power transmission technology to optimize rotation speed and maximize torque while minimizing power consumption.

In addition the TWISTER® Low Speed Surface Aerator includes these features:

- Flange coupling for high torque, long lifetime performance.

- Three pod float design for in-basin stability.

- Standard motor for easy availability and replacement.

- Float or fixed mounted units to meet process requirements.

- Minimum 2.0 gearbox safety factor assures long life.

All TWISTER aerators consist of a motor mounted to a gear reducer and an extended shaft. A specially designed rotor is attached to the bottom of the extended shaft. The aerator is positioned so the rotor is partially submerged in the wastewater when activated the TWISTER aerator turns at a slow speed (typically 40 to 100 rpm). Specially designed fins on the rotor then pump massive amounts of water into the air in a fine spray. These very small droplets create a 360-degree circular pattern.

High transfer of oxygen results from the large surface area to volume ratio of the water droplet and its long exposure time in the air during its spray trajectory. Oxygen transfer is further enhanced by taking advantage of the oxygen transfer gradient of O2 deficient water at the bottom of the basin by pumping it up and exposing it to air above the water surface to promote faster mass transfer from ambient air to water droplet.

The deep pumping action of the TWISTER aerator generates effective localized mixing to optimize many wastewater treatment processes. The TWISTER aerator is ideal for many industrial treatment processes requiring fast and efficient oxygen transfer such as pulp & paper, food processing and others.