Lime Saturators

Hydroflux is proud to be Australia’s first water treatment and technology company to achieve Climate Active carbon neutral certification for our entire organization. As part of our climate change mission, we continue to research, develop and invest in sustainable technologies.

Now our journey continues – our main range of water technology and associated chemical products are Climate Active certified as carbon neutral. To read more on our journey, click HERE

The lime saturator is a process unit, designed to make saturated lime water for control of the pH and alkalinity of water in the Water Treatment Plant.

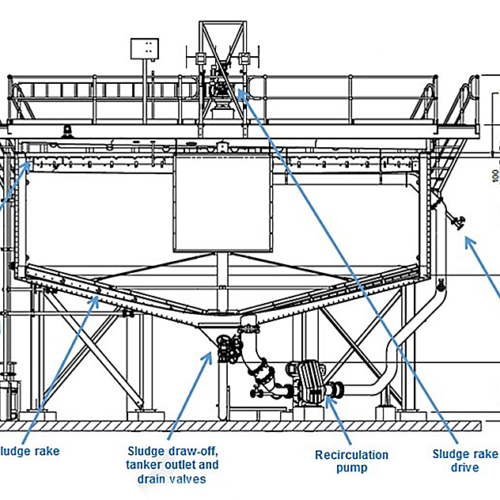

The unit consists of a saturator-clarifier tank and weirs, a hopper, and a sludge rake. The unit includes an inlet and outlet, lime recirculation and slurry dosing, and spent lime solids sludge wasting. Sampling points are also provided.

Hydroflux Epco have extensive expertise and references for Lime Saturators/Clarifiers as follows:

- Over 330 clarifier systems manufactured since 1962, numerous operational in lime saturator applications.

- Robust construction with proven sludge removal systems (VeeMax®, LogMax® and HeadMax®)

Find out more

- Proven bridge construction

- Elimination of dead zones

- Free standing design in steel construction

A number of designs and configurations are available, these include:

-

- Centre Drive

- Peripheral Drive

- Full bridge

- Half bridge

Lime slurry (calcium hydroxide) is fed into the centre of the saturator tank from an inlet pipe, which also carries treated feed water into the tank. The lime-dosed feed water mixes with recirculated flow from the saturator inside a baffle, flowing down through diffuser plates and underneath the baffle to equalise flow into the remainder of the clarifier.

The lime water then slowly rises to the top of the clarifier and flows over V-notch weirs into a collection trough, leading to storage in a limewater tank. The lime-treated water has a higher pH and alkalinity compared to the treated water feed.

This allows for its use in controlling the quality of water for other treatment processes that affect pH and alkalinity, such as coagulation. Excess lime remaining (after the treated water is saturated in the baffle) settles to the bottom of the clarifier to form a slurry, which is kept slowly moving and disposed of through a sludge line at the bottom of the hopper. The saturator also features a recirculation line at the bottom of the hopper, which returns unused lime to the feed well for re-mixing.