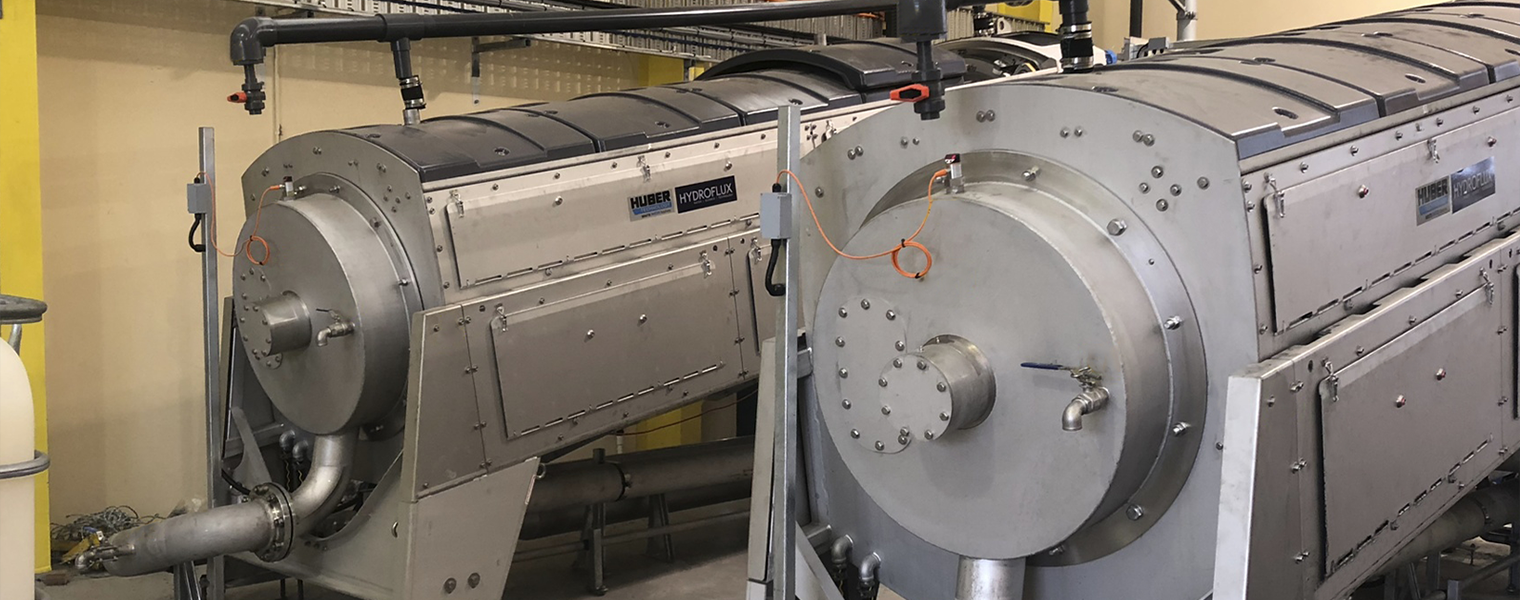

HUBER Rotary Screw Press – High Capture Rates Without the Need for Secondary Filtration

May 8, 2020

Excellent performance, low energy and low maintenance are the main reasons why there over 1500 HUBER QPRESS Rotary Screw Press units in operation around the world. Specific to Australia and New Zealand there are some 60 HUBER units in operation.

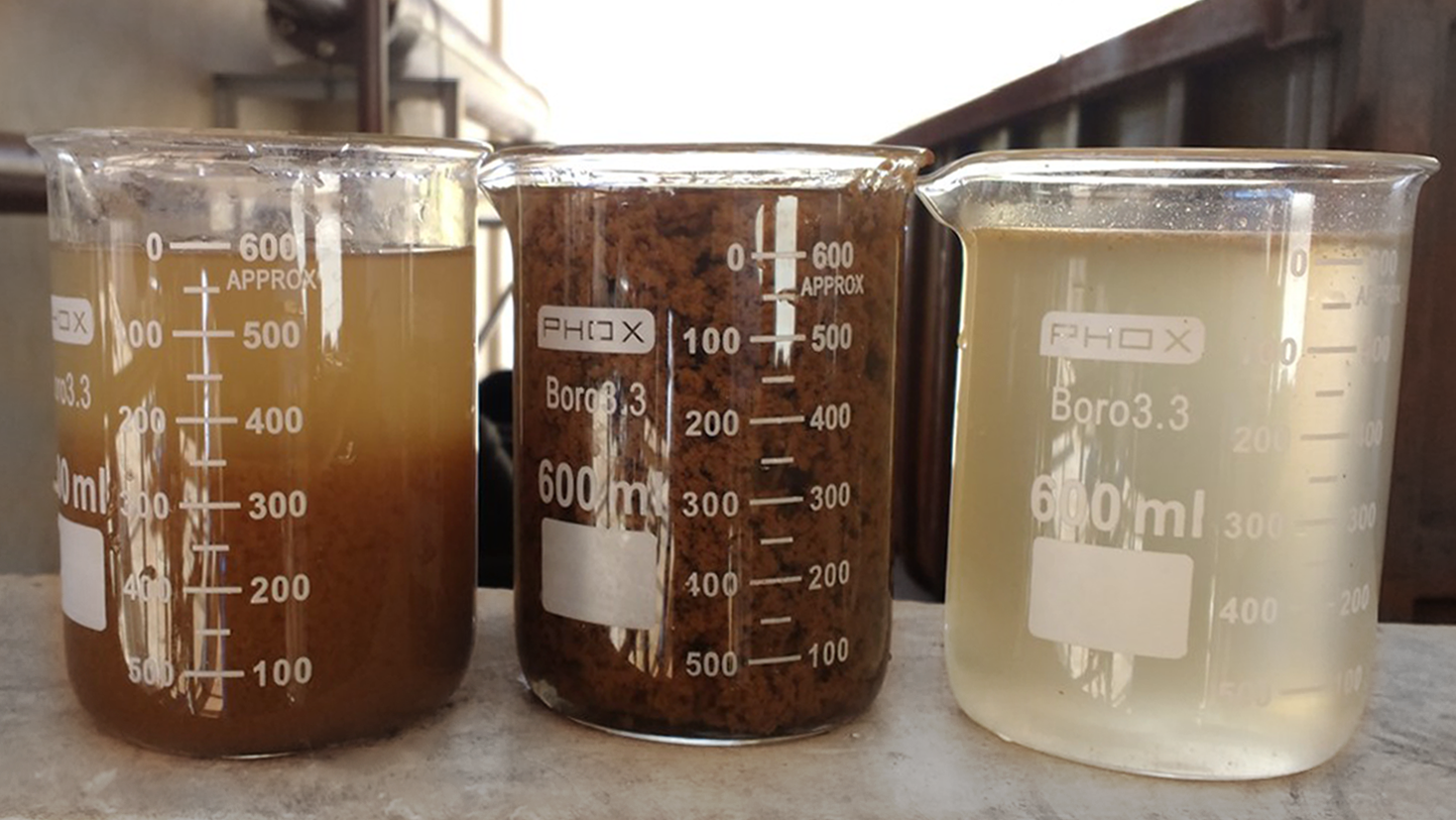

“HUBER’s sizing is based on achieving a >95% capture without the need for any further downstream treatment of the filtrate to increase capture. We have verified this in our own research trials and operating sites across Australia and New Zealand. HUBER’s Rotary Screw Press was specifically developed for the municipal sewage market and to meet customer needs for a low energy, high performance sludge dewatering technology.

“Our design approach provides the perfect balance between throughput, cake solids and high capture. We do not need additional mechanical equipment for filtrate quality management” says Daniel Potente of Hydroflux Epco Pty Ltd.

The unnecessary additional footprint, CAPEX and operational/maintenance costs associated with separate filtrate solids recovery devices are not part of the equation with a HUBER Q Press.

The technology has also been applied to a variety of industrial sludge streams including meat, dairy, manure and tunneling applications.

Up Next

Categories

- Tradeshows

- Climate

- Community Engagement

- Corporate Announcements

- Group News

- Newsletters

- Product News

- Project Announcement