Pump Station Screen

The Unique Pump Station Screen is part of the range of high quality German manufactured screens and has been designed specifically for screening solids in pump stations.

Solids collecting in pump stations can cause many problems including pump blockages. The HUBER pumps station screen is designed to remove solids from pump stations before the inlet of the pumps, thus increasing the reliability and longevity of the pumps.

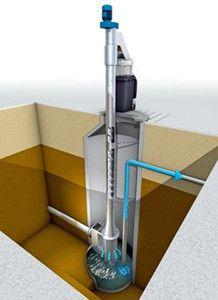

The ROTAMAT® RoK 4 screen is the ideal solution for new pumping stations or for retrofits. It is an automatically cleaned fine screen with vertical conveying, dewatering and compaction of screening materials.

Captured screenings are lifted vertically and compacted at the same time. The compacted screenings are discharged into a container or bagging unit.

Find out more

The ROTAMAT® Pumping Stations Screen RoK 4 is directly connected to the sewer pipe by means of a flanged inlet.

The wastewater enters the screen through the inflow chamber with integrated bottom step. As the water streams through the perforated plate into the pump sump, the screenings are retained. An auger, with a brush attached to its flights, rotates within the screen basket and cleans the screen. As the screenings are elevated by the auger, they are dewatered up to 40 %.

The compacted screenings are discharged into a container.

The RoK 4 consists of a vertical perforated screen basket and a shafted auger in a vertical tube. The wastewater flows through an inflow connection and a chamber into the screen basket.

Within the screen basket the flights of the screw are equipped with wear-resistant brushes for effective cleaning of the screen. As the screenings are gradually elevated by the auger, they are dewatered. The compacted screenings are discharged into a container or endless bagging unit thus eliminating odour nuisance.

The screened wastewater flows off by gravity or is pumped to a higher level. The filtrate drains through a hose back into the inlet chamber. The top of the inflow chamber is open and serves as an emergency bypass so that the machine can be submerged without problems, e.g. in case of a power failure. The integrated bottom step prevents back-flooding into the sewer system and thus undesired deposits in the incoming sewer

- The ROTAMAT® Pumping Station Screens RoK 4 offer outstanding advantages:

- Automatic screening, lifting and compaction in a single compact unit

- Optimal solids retention by means of two dimensional screening (perforated plate)

- Prevent clogging and tressing in pump stations and manholes

- Integrated bottom step to prevent deposits in the incoming sewer

- Easy to install into existing structures

- Availability of completely submerging the screen