Spiral Screens

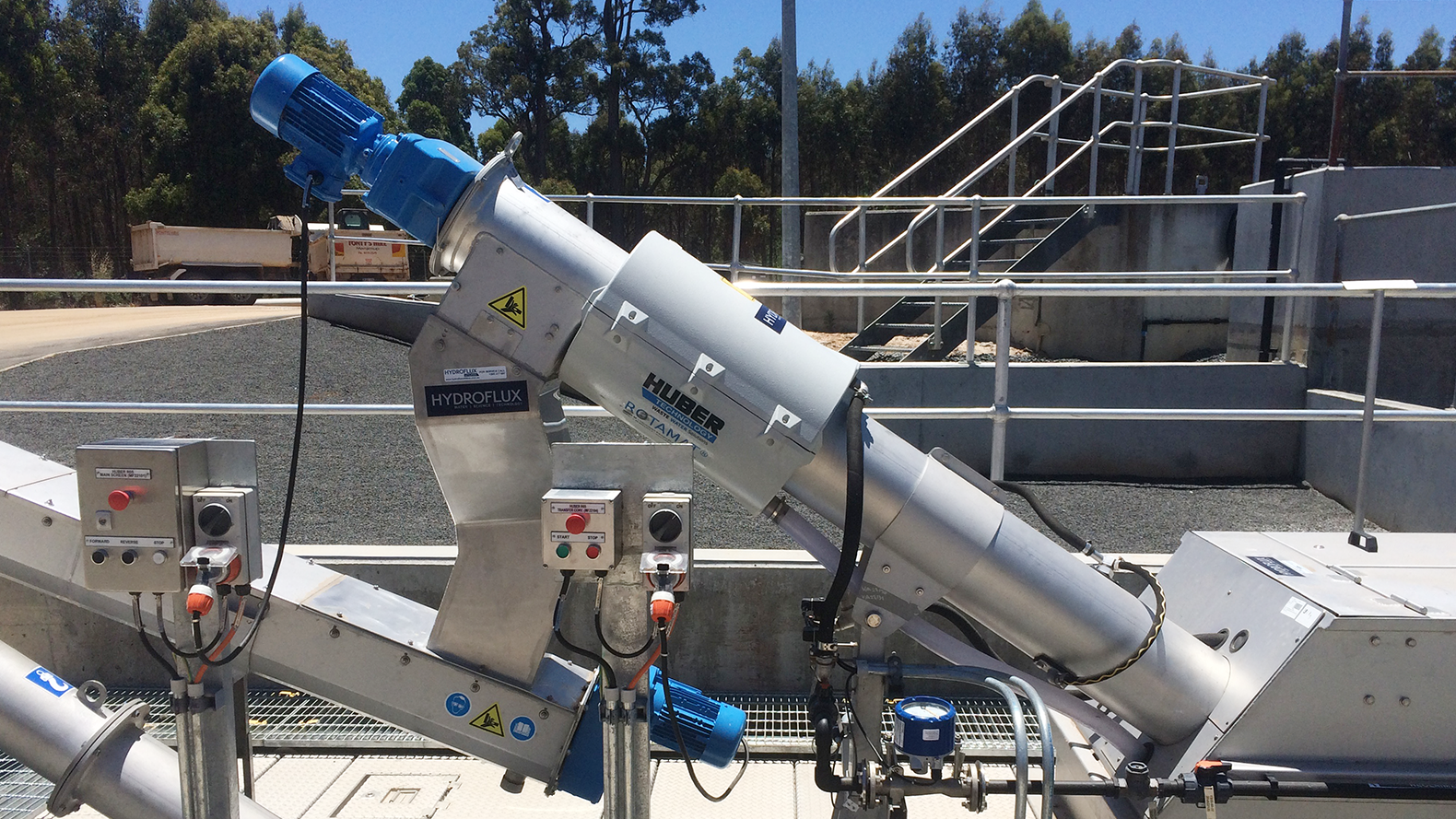

The HUBER Ro9 spiral Screen is one of the range of high quality German manufactured screens designed specifically for smaller sewage treatment plants, up to 5ML/day.

The ROTAMAT® Micro Strainer Ro 9 operation is based upon a unique system that allows combination of screening, washing, transport, compaction and dewatering in a single unit. All units are fabricated from high quality stainless steel and can be installed either directly in the channel or above ground in a separate tank.

The screening elements can be either wedge wire bar spaced at 0.5-6mm, or 1-6mm perforated drums can be used. Depending on the aperture size selected and the screen diameter (screen basket diameters of up to 700 mm are available),the throughput can be individually adjusted to specific site requirements.

Find out more

The ROTAMAT® Micro Strainer is installed directly in a channel or into a separate tank. The wastewater flows in through the open front end of the screen basket and through the screen bars or perforations. Solids are retained by the screen basket, whereby the separation of floating, settling and suspended solids is dependent upon the screen bar spacing or perforation size.

Blinding of the screen surface generates an additional filtering effect so that solids can be retained that are smaller than the bar spacing or perforation.

The machine starts to operate when a certain upstream water level is exceeded due to screen surface blinding. A robust stainless steel screw removes the screenings from the screen basket surface. Additional cleaning is achieved by wear-resistant brushes fitted to the screw flights.

The screw conveyor transports the screenings through a closed and inclined pipe. Whilst the screenings are transported, the screw conveyor dewaters and compacts them without any odour annoyance prior to discharging them into the customer’s container or a subsequent conveying unit.

To optimise the treatment process an integrated screenings washing system IRGA can be provided. It improves the carbon/nitrogen ratio of the pre-treated wastewater whilst reducing the cost of screenings disposal.

The ROTAMAT® principle allows for integration of the screenings washing system directly in the trough and/or the lower end of the rising pipe. As the soluble matter is separated from the inert material, faeces are virtually completely washed out which leads to a significant weight reduction.

Benefits of screenings washing

- Easy retrofit

- Minimised disposal costs for screenings

- Improved operating and hygienic conditions

- Virtually complete wash out of faeces

- Weight reduction by approx. .50%

- Dewatering performance of up to 40%DS

- Proven in over 3000 installations

- Purpose made shaft screw provides trouble free operation

- Full stainless steel construction (no mild steel screws)

- Optional Integrated screenings washing

- Quick and easy installation, even as a retrofit

- Reliable self-cleaning of the screening area by means of the stainless steel screw flights and wear-resistant brushes

- All stainless steel construction, therefore virtually unlimited life and no maintenance

- Encapsulated, odour-free plant