AEROSTRIP® Fine Bubble Diffusers

Hydroflux is proud to be Australia’s first water treatment and technology company to achieve Climate Active carbon neutral certification for our entire organization. As part of our climate change mission, we continue to research, develop and invest in sustainable technologies.

Now our journey continues – our main range of water technology and associated chemical products are Climate Active certified as carbon neutral. To read more on our journey, click HERE

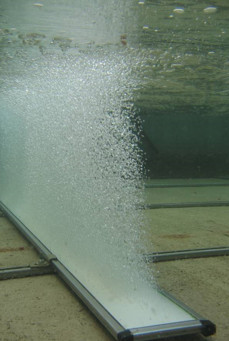

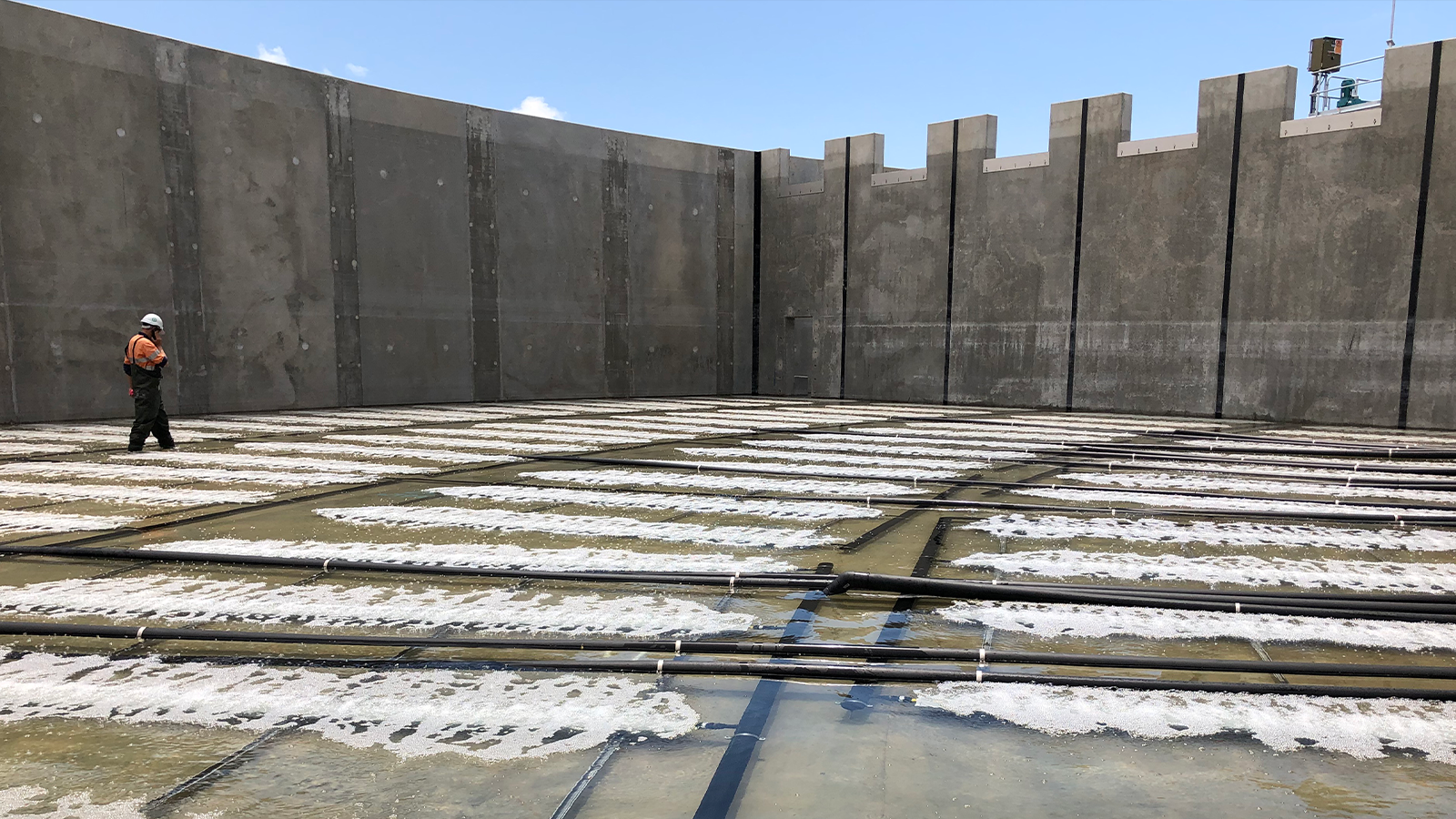

The AEROSTRIP® Fine Bubble Membrane Diffuser is a strip diffuser, for use in continuous and intermittent biological processes.

AEROSTRIP® Diffusers by AquaConsult of Austria have been in operation since the early 1990’s and are providing significant benefits to numerous wastewater treatment plants with over 2000 installation worldwide including many industrial and municipal plants throughout Australia.

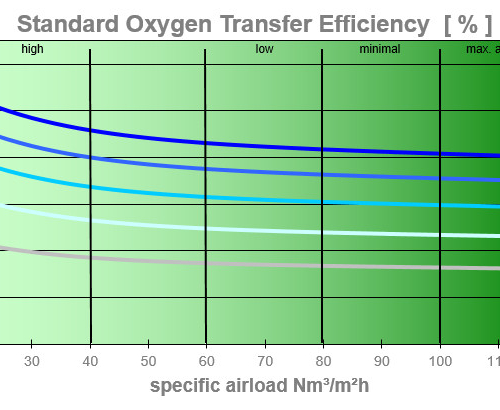

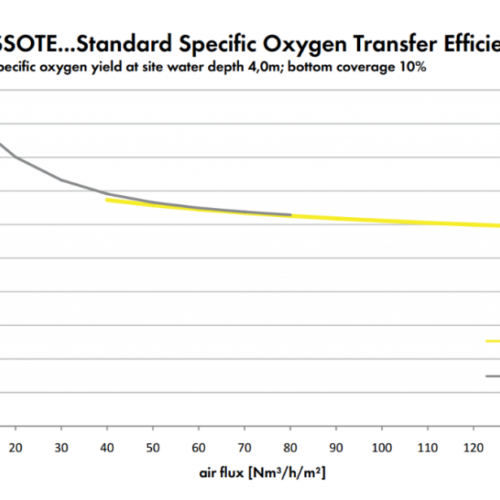

The main benefits of the AEROSTRIP® diffusers is the significant power savings due to the high oxygen transfer rate 4.0-5.0 kgO2/kW and robustness/long life of the membrane, which is greater than 12 years. And this is without fouling or loss of pressure.

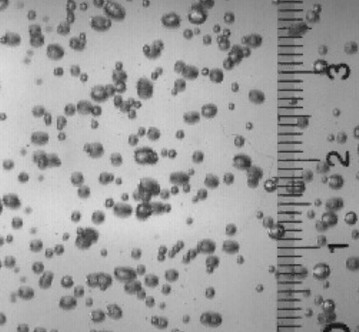

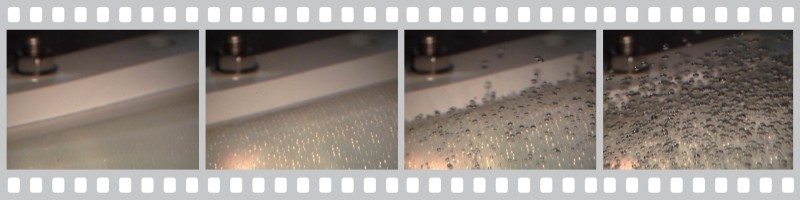

As the AEROSTRIP® Diffuser is fed with air, an air cushion forms underneath the membrane and the micro-perforations open partially. As air flow increases, the number of open perforations increases. The fine bubbles emerge and rise slowly with an oscillating motion. The 1mm bubbles provide high specific area and great stability. This leads to high oxygen mass transfer.

The AEROSTRIP® Diffusers are suitable for use in conventional activated sludge plants, sequential biological reactors, membrane bio reactors and virtually any aerobic wastewater treatment process.

Hydroflux Epco can provide an instant aeration design for your WWTP utilising a proprietary AEROSTRIP® Design Tool.

Find out more

AEROSTRIP® Fine Bubble Membrane Diffusers offer numerous advantages, when compared to other fine bubble diffusers.

- Between 4.0—5.0 kgO2/kW transfer efficiency

- Ultra-Fine bubble size provides of highest transfer rates

- Oxygen transfer efficiency up to 60%

- Non clogging design

- PU membrane; long life (greater than 12 years)

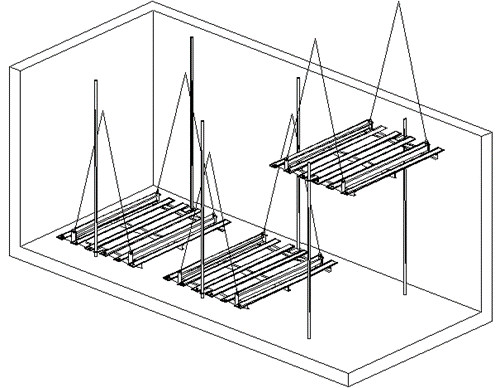

- Greater coverage of the reactor floor with strip profile

- Can be mounted on the base of tank

- Intermittent and/or continuous operation

- Can be used in high MLSS reactors (MBR) at > 15,000mg/L

- Multiple lengths and configurations allows for installation in any tank shape or size

- Documented proof of efficiency and durability

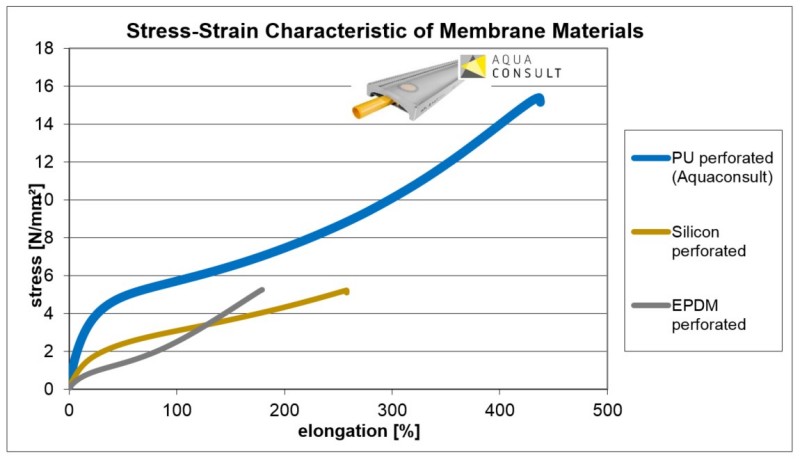

AEROSTRIP®’s polyurethane membrane does not contain any plasticisers or fillers.

Membranes using these additives, like the commonly used materials EPDM and Silicon, tend to get brittle over time resulting in a loss of efficiency and the costly exercise of replacing the diffusers. AEROSTRIP®’s polyurethane membrane has a proven life of over 10 years with minimal drop in material properties and performance.

AEROSTRIP®’s perforation density of 400 000 pores per m² produces an ultrafine bubble pattern for a wide air flow range. The number of active pores, which diffuse air to water, varies with air flux. The higher the flux, the higher the number of diffusing pores. This ensures a constant small bubble size for the whole operating range of the AEROSTRIP diffusers.

During the perforation process, the membrane pressure drop is constantly measured. If measured value departs from specified value, perforation style is immediately adjusted. This ensures that air is distributed equally inside the aeration tank and the maximum amount of oxygen gets diffused into the water.

Control strategies are implemented to mitigate fouling effects on the membrane with regular automated blow down cycles to release pressure in the header and flush the membrane.

Every single AEROSTRIP® membrane and diffuser is tested at the factory in Austria before delivery.

– The AEROSTRIP® Diffusers are assembled by skilled personnel on half-automated assembly lines and certified to ISO 9001

– Each individual AEROSTRIP® polyurethane membrane is tested prior to assembly:

-

-

- FTIR – Spectroscopy for material inspection

- Tensile testing machine for determination of material constants

- Stereo-microscope for an accurate visual inspection

-

– All AEROSTRIP® Diffusers are tested at the same flux before delivery for;

-

-

- Leakage

- Bubble pattern, size and uniformity

-

– AquaConsult have an in-house testing facility for measuring oxygen capacity

– A unique serial number is stamped on all diffusers for traceability

Hydroflux Epco can provide an instant aeration design for your WWTP utilising a proprietary AEROSTRIP® Design Tool.

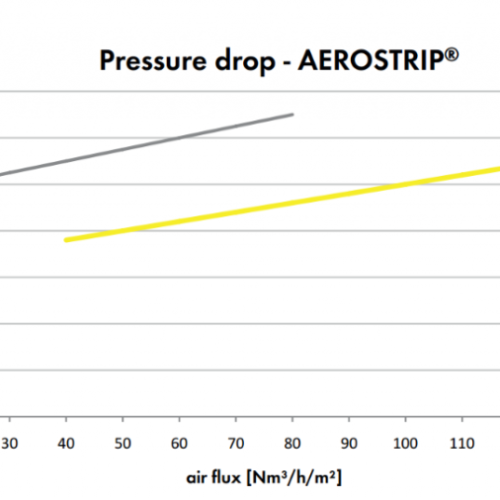

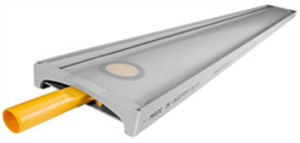

Hydroflux Epco supply two types of Low Flux (10-80 Nm³/h/m²) AEROSTRIP® modules, both ideal for maximum performance in standard municipal and industrial applications.

For higher flux rates, high solids loading’s and/or high fouling applications we recommend the AEROSTRIP® Phoenix Membrane.

| AEROSTRIP® TYPE T – LOW FLUX | AEROSTRIP® TYPE Q – LOW FLUX |

|

|

|

|

Hydroflux Epco can provide an instant aeration design for your WWTP utilising a proprietary AEROSTRIP® Design Tool.

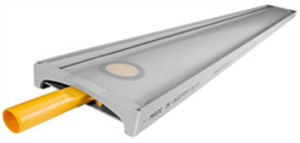

Hydroflux Epco supply two types of High Flux (40-120 Nm³/h/m²) AEROSTRIP® Phoenix modules, both ideal for maximum performance in high solids loading’s and/or high fouling municipal and industrial applications.

For maximum performance in standard municipal and industrial applications we recommend the Low Flux AEROSTRIP® Membrane.

AEROSTRIP® has developed the Phoenix membrane for even higher reliability in industrial applications, membrane bioreactors and aerobic digestion processes.

Industrial applications can have higher fouling factors due to the presence of impurities or high organic content. Similarly, for membrane bioreactors and digesters, the high suspended solids loads result in an increase in the amount of diffusers required to achieve the design oxygen transfer.

| AEROSTRIP® TYPE T – HIGH FLUX | AEROSTRIP® TYPE Q – HIGH FLUX |

|

|

|

|

The Phoenix membrane is yet another world leading innovation by AEROSTRIP®. This membrane has an enhanced micro perforation pattern that allows high air flow rates with reduced pressure loss, making it ideal for high loading applications.

This means less diffusers for high fouling or low alpha factor applications.

Hydroflux Epco can provide an instant aeration design for your WWTP utilising a proprietary AEROSTRIP® Design Tool.