Hoppers

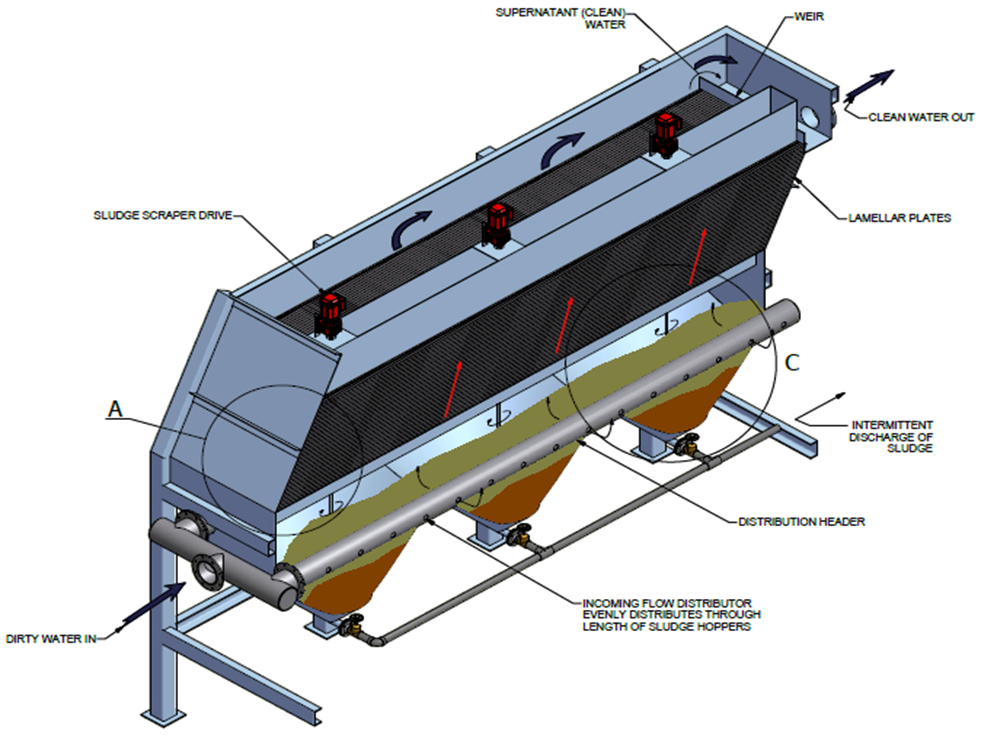

HiFlowTM can be provided with a single or multiple sludge removal hoppers. In larger systems the use of multiple hoppers results in a reduced tank height and hence a cost benefit.

The hoppers can be fitted with mixers to provide effective and reliable sludge removal. This ensures that no dead zones develop and is ideally suited to sticky or viscous sludge streams.

Each hopper is fitted with an isolation valve is connected to a single sludge withdrawal manifold for easy transfer of thickened sludge.

Find out more

- Multiple hoppers reduce lamella tank height

- Less cost associated with installation and ancillaries such as access platforms

- Reliable and simple method for sludge removal

- High degree of sludge compaction

- Optional mixer installation for viscous sludge streams

- Easy discharge via single sludge withdrawal manifold

The HiFlowTM lamella separator is a high rate solids separation process that has 1/10th of the physical footprint as compared to conventional circular clarifiers. It is used as a primary and secondary clarifier in sewage, primary clarifier in water treatment and primary clarification of industrial wastewater.

Hydroflux Epco have extensive expertise and references for clarification/lamella technology as follows:

- Over 330 clarifier systems manufactured since 1962

- Highly effective plate pack surface area

- All stainless steel lamella pack construction

- Robust construction with proven sludge removal systems (VeeMax®, LogMax® and HeadMax®)

- Laminar flow conditions

- Free standing design in steel construction

- Concrete tank designs for larger applications

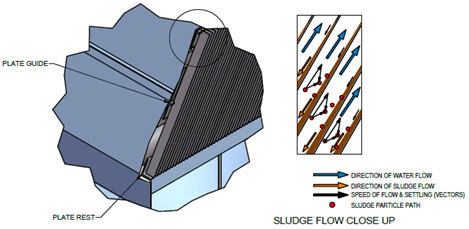

A series of inclined lamella plate packs are used to increase the effective surface area of the unit and to overcome hindered settling.